Pretension

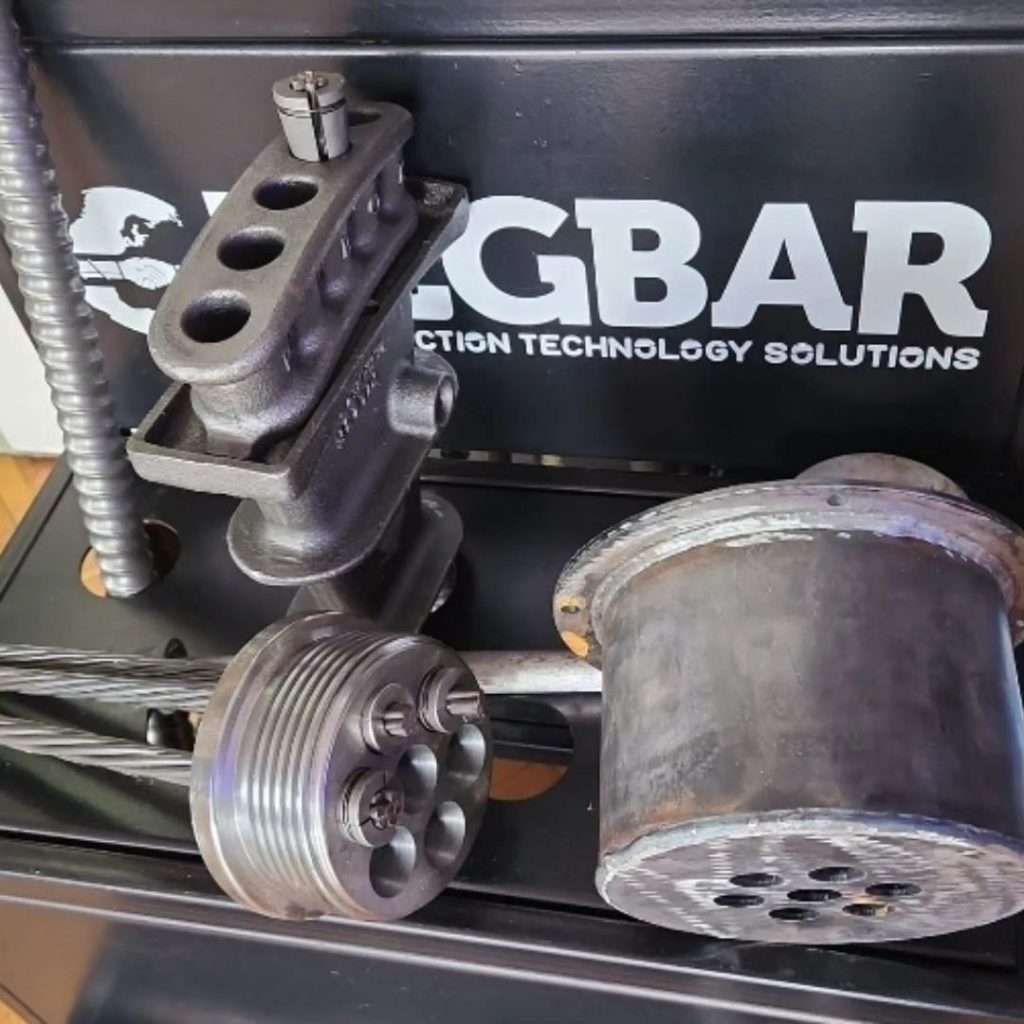

The self-drilling anchor bolt device (also known as Threaded Hollow Bars) makes your job much easier, as it is capable of performing procedures of drilling, anchoring and injection all at once. There is a hollow interior of the self-drilling anchor bolt, a threaded exterior and a drill bit that is used for drilling. The self-drilling anchor bolt's hollow interior enables air and water to freely move through the drilling process, flushing the particles. After completion of the drilling process, it also enables immediateinjection. For fractured or hard rock formations as well as uneven ground conditions (such as gravel, soft, clay and non-homogeneous soil), self-drilling anchor bolts present a specific bolting solution. Regbar Strong Anchor Plates are especially suitable for heavy industrial structures. Rebar anchors with stud head also provide structural connections for thinning concrete structures. Regbar Strong Anchor Plates are also available in extra long diameters to eliminate the need for additional reinforcement.

Pretension

Anchorage Heads

Regbar Multi-String Prestressed Systems, have been used for years in the construction of bridges, buildings, tanks and many other structures that require engineering reinforcement and support elements. Regbar provides Design and Development, Engineering, Production and Supply Installation, Technical Training, Installation Supervision, Inspection or Maintenance services for Prestressing Systems. Regbar Pre Stressing Systems are known for its superior load bearing performance, durability and simple design. Regbar Pre Stressing Systems significantly contributes to long life of structures by virtue of its high-quality corrosion protection methods. They are used on slopes such as Regbar Anchor and Pile Systems and related product lines and for geotechnical applications as excavation stabilization in a wide range.

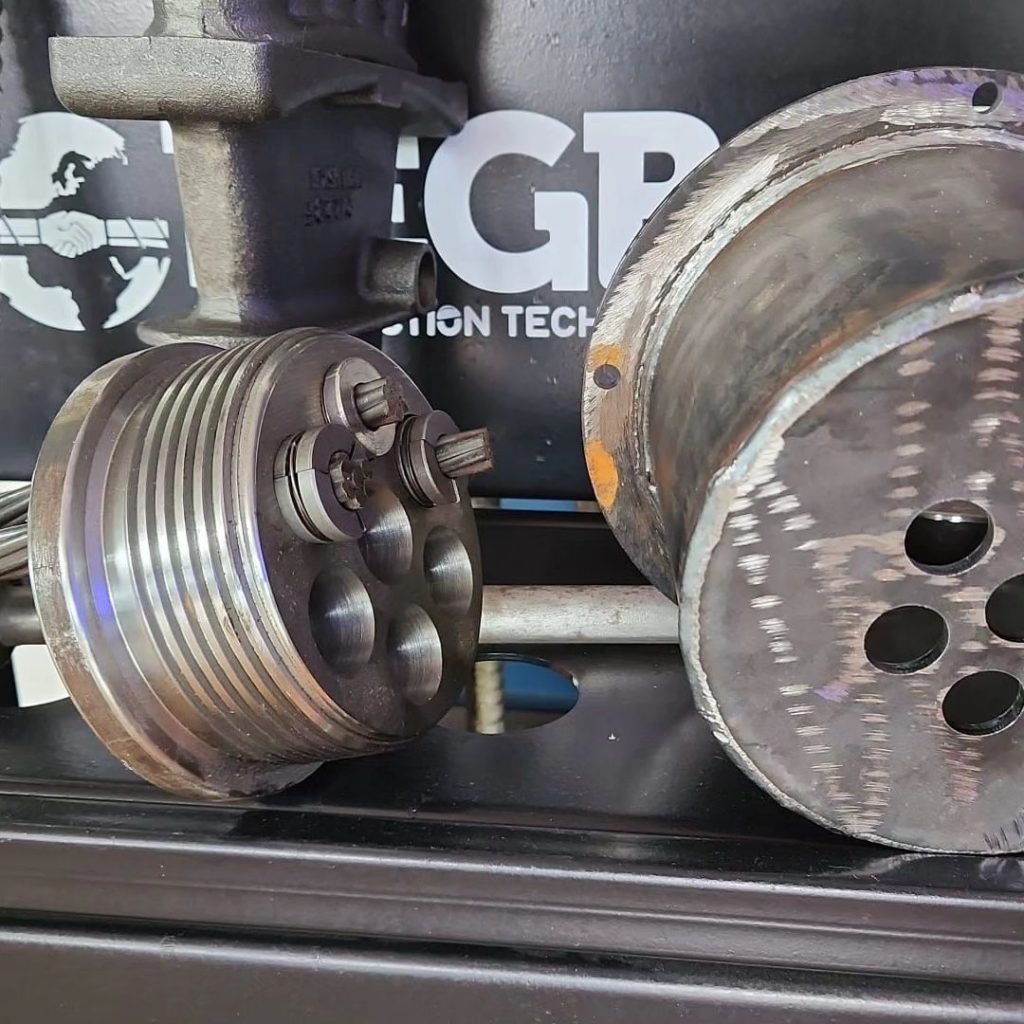

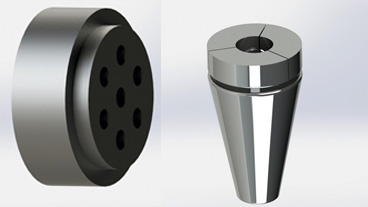

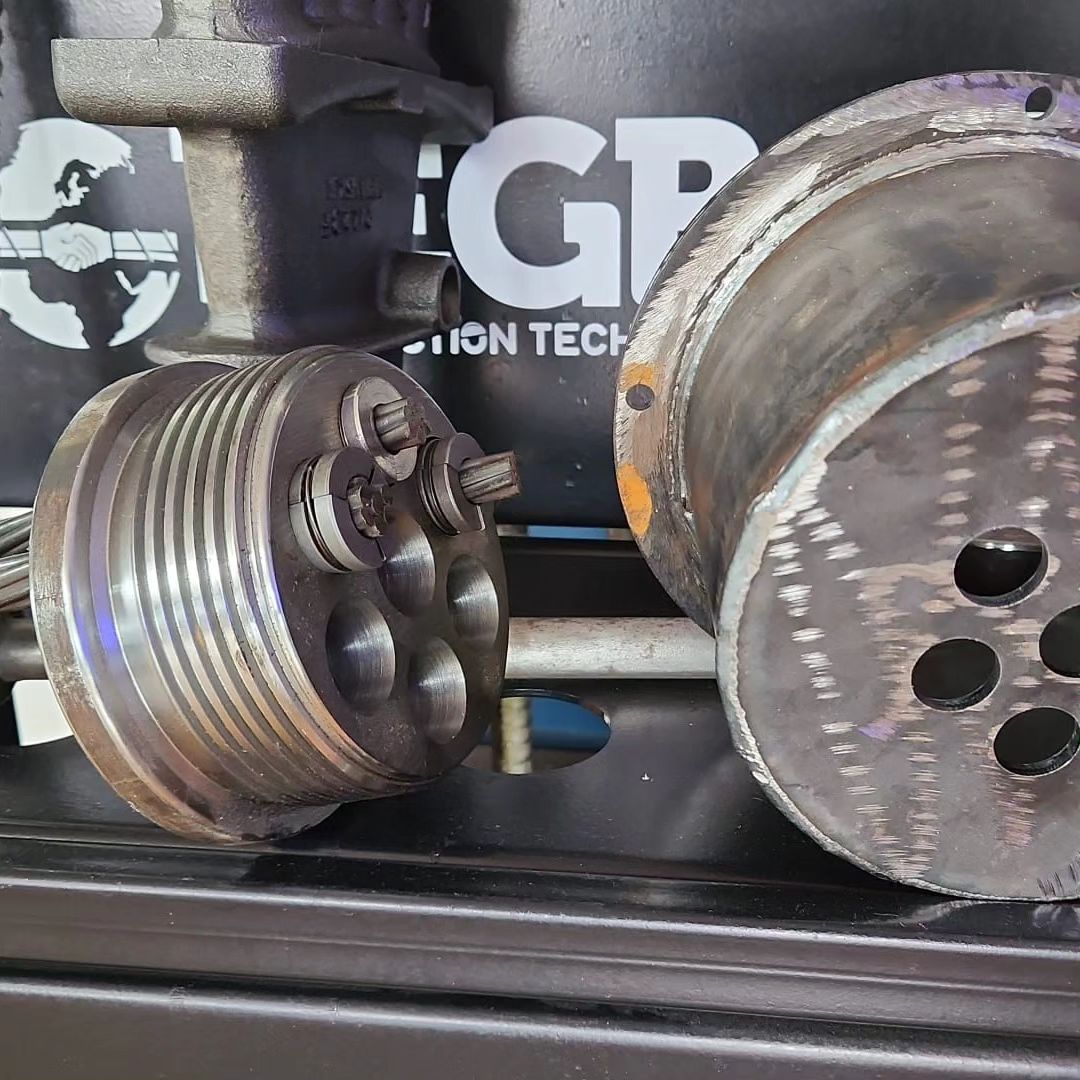

The anchorage cover/ head used in the pre-stressing anchorages; this part which works with this head plate enables to transfer the pre-stressing force into the sheathing surface.

Anchor Grips

Diameter and number of the tendon materials, dimensions of load distribution plate, diameter of anchor head and number of holes, number of anchor grips are calculated according to the anchor loads depending on the project. Regbar anchor heads are available in all sizes and diameters in our stocks.

Anchor heads and grips are designed according to types and number of spiral steel ropes that form the tendon. Threaded grip clamps-grips are used to fasten the anchor tendons to head plate.

The diameter and number of tendon material, the size of load distribution plate, the diameter and hole number of anchorage head, the number of anchorage wedges are calculated according to the anchorage loads in accordance with the project. You can supply the anchorage heads in Regbar brand in any height and diameter from our stocks. The anchorage heads and grips are designed according to the type and number of spiral steel ropes which make tendon. The grip clamps-wedges (grip) are used to fix the cover plates of the anchorage tendon.

The diameter and number of tendon material, the size of load distribution plate, the diameter and hole number of anchorage head, the number of anchorage wedges are calculated according to the anchorage loads in accordance with the project. You can supply the anchorage heads in Regbar brand in any height and diameter from our stocks. The anchorage heads and grips are designed according to the type and number of spiral steel ropes which make tendon. The grip clamps-wedges (grip) are used to fix the cover plates of the anchorage tendon.

Regbar manufactures the plates in requested sizes according the measurements and demands in the projects. Regbar anchorage plates may be prepared in accordance with the demands and needs as a special production as well as the standard drilled holes. In addition, the plates may be manufactured from the stainless steel according to the demands for the projects including the sensitivity to corrosion. Regbar suggest the protective caps appropriate for your Project to protect the plates and grips.

Tensioning Anchors

Pre Tension tensioning anchors help to anchor and stretch the ropes. These are designed according to the principle of anchoring each rope individually by means of compressors.

The prestressing force is transferred to concrete by a rigid anchor plate.The spirals surround too much concrete in the zone behind the anchor plate. The tensile forces in the anchor zone should be met with an additional soft reinforcement

The reinforcement is determined by considering the shape and dimensions of the anchor plate as well as

the dimensions of the end region. Stretching anchors can also be used as fixed anchors. In this case, the anchor head must remain stable during the tensioning process.

More Information

Download the catalog to see all our productsContact us

Call us for Information and OfferWhy Us?

Global Company

Quality Control

Sale Support

Other Products

Tunnel Support

Equipments

Anchorage

Self Drilling Rockbolt

Anchor Bolt

Tierod

Rockbolt

Soilnail

Post Tensions

Plates

Pretensions

Expansion Bolts

Fiber Rockbolt

Split Set

Regmiks

Nut Washer Eyebolt

BoltStud

Plastic Spacer

Tunnel Support Equipment