Tunnel Support Equipment

The requested special design products are manufactured in our factory and dispatched to field as ready-to-implement. Our machine park mainly includes the following; Profile bending machine, plasma and laser cutting machines, CNC Lathe and Vertical Machining Center, Saws, Gas Metal Arc and Argon Welding Machines, Sheet Cutting Machines and plastic injection machines for protective accessories. All kinds of steel design, manufacturing and application are performed depending on the requirements of projects.

- ► Regbar mainly manufactures the below tunnel support equipment.

- ► We manufacture Rock Bolts and Anchorage, Lattice Girder, Tunnel Lining, Mold Lining and Profile Lining (Profile Arch).

- ► Having a great experience in tunnel equipment, soil stabilization equipment and accessories, Regbar has been involved in numerous subway and tunnel projects regarding application of Umbrella System.

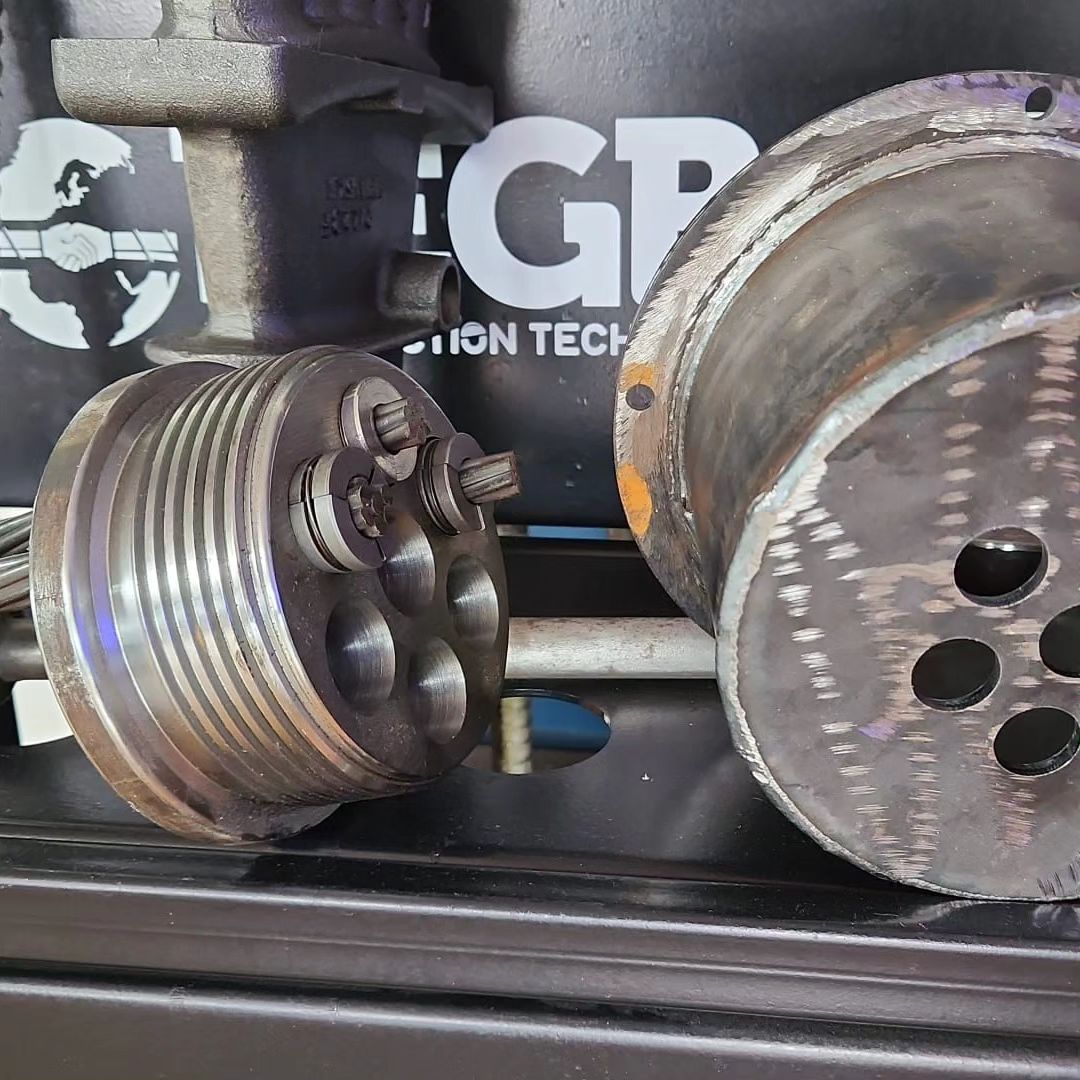

BIBLOCK CIRCUMFERENTIAL CONNECTION

Biblock system are circumferential connectors that can be custom desgined for tunnel segment production. 2 most commonly used sockets, 1 pin and 1 centering ring. In some types, the pin and centering ring are molded together. The cutting capacity is guaranteed by the centering ring followed by the pin. Tensile strength depends on pin / socket interaction. Different pins, sockets and centering rings are available

Biblock system are circumferential connectors that can be custom desgined for tunnel segment production. 2 most commonly used sockets, 1 pin and 1 centering ring. In some types, the pin and centering ring are molded together. The cutting capacity is guaranteed by the centering ring followed by the pin. Tensile strength depends on pin / socket interaction. Different pins, sockets and centering rings are available

Advantages;

- Cost savings per mold / ring;

- Fast segment setup;

- Safer field conditions;

- Less staff needed on the tunnel face;

- Better segment alignment;

- Smooth inner tunnel surface;

- Lower water friction in hydraulic tunnels;

- Dielectric insulation throughout the tunnel

- Lifting sockets can be used for a variety of precast Two functions

These designed sockets can be used with the TBM segment mounting system to lift the segments into place in the ring or for primary or secondary injection across the segments.

SEGMENT GASKETS

Gaskets produced and vulcanized by extrusion method are combined with heat welding process. The contact between the concrete ring and the gasket occurs in the area of the claw protrusions of the gaskets. The contact between the gaskets takes place in the dorsal area of the gaskets so that they overlap.

By determining the difference between concrete gaps, the pressure values of the ring gaskets that will overlap.

TUNNEL BORING MACHINE LUBRICANTS

Head Seal Grease for Tunnel Boring Machines (TBM) Tunnel Boring Machine Exclusive Grease Oil Tunnel boring machines is an exclusive grease oil. It effectively protects the main bearing and prevents soil, protects main bearing seal from water or dust. It is formulated to resist high water and soil pressures and has excellent lubrication and pumping properties, and adheres to all surfaces. It contains biodegradable and renewable raw materials.

Tail Seal Grease for Tunnel Boring Machine (TBM)

Due to its TSG consistency, it is a pumpable seal. Due to its consistency, this grease does not decompose under high mechanical pressures during tunnel boring and its lubrication property protects the tails. In addition, the product reduces the heat resistance. It reduces the risk of flame formation in the tunnel.

Multi-purpose EP2 grease for Tunnel Boring Machines (TBM)

Advantages and benefits: RX3 is a highly biodegradable multi-purpose calcium thickened EP2 grade grease designed for main bearing lubrication, as a screw conveyor drive assembly grease and as a rotary swivel grease. Properties: Contains antioxidants, corrosion inhibitors and EP/AW additives. Offers good mechanical stability, load carrying capacity and corrosion protection, which makes it suitable for loaded bearings as well as wet environments. High quality multipurpose grease suitable for a wide range of plain and rolling bearings. Highly biodegradable and based on renewable raw materials.

More Information

Download the catalog to see all our productsContact us

Call us for Information and OfferWhy Us?

Global Company

Quality Control

Sale Support

Other Products

Tunnel Support

Equipments

Anchorage

Self Drilling Rockbolt

Anchor Bolt

Tierod

Rockbolt

Soilnail

Post Tensions

Plates

Pretensions

Expansion Bolts

Fiber Rockbolt

Split Set

Regmiks

Nut Washer Eyebolt

BoltStud

Plastic Spacer

Tunnel Support Equipment