Umbrella Pipe System

The umbrella arch system, also known as the canopy tube method, is increasingly utilized in tunnel construction, particularly in geologically challenging or high-risk areas. This technique involves the strategic installation of a protective arch of steel pipes, often referred to as "canopy tubes" or "spiles," around the tunnel’s excavation perimeter. The primary purpose of this system is to stabilize the surrounding ground and mitigate the risk of surface subsidence, which could otherwise lead to structural damage to buildings or infrastructure located above the tunnel route. The selection of the appropriate pipe diameter is crucial, as it directly impacts both the structural integrity and economic viability of the project. A properly dimensioned umbrella arch system can significantly enhance tunnel stability by distributing loads and reducing deformation within the tunnel lining. Conversely, undersized pipes may compromise the system's effectiveness, while oversized pipes can lead to unnecessary cost increases and extended project timelines. Thus, the choice of pipe diameter must balance the technical demands of the ground conditions with the project's budgetary and scheduling constraints. In summary, the umbrella arch system is a vital component in modern tunnel construction, particularly in areas with poor ground conditions, as it offers an effective means of protecting both the tunnel and the structures above it from potential damage.

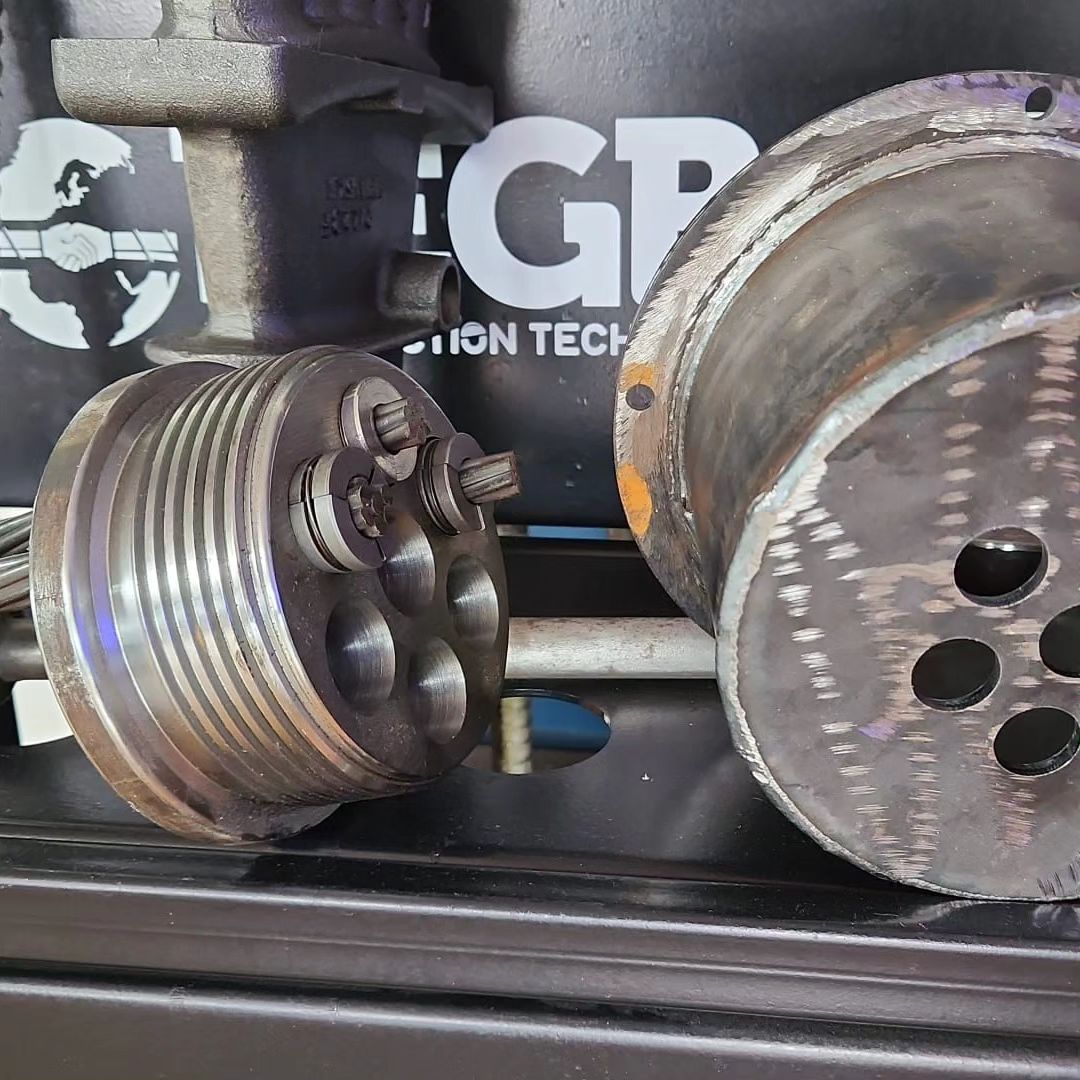

Umbrella pipe adabter pin and box

The Umbrella Pipe Adapter, featuring both pin and box connections, is a crucial component in tunnel stabilization systems, particularly in the umbrella arch method. This adapter ensures a secure and seamless connection between the drilling rig and the steel pipes used in the canopy tube system. The pin and box design allows for efficient assembly and disassembly, facilitating precise alignment and strong joint integrity under high-stress conditions. Its robust construction is engineered to withstand the demanding environments of tunnel construction, ensuring reliable performance and minimizing the risk of connection failure during operations.

More Information

Download the catalog to see all our productsContact us

Call us for Information and OfferWhy Us?

Global Company

Quality Control

Sale Support

Other Products

Tunnel Support

Equipments

Anchorage

Self Drilling Rockbolt

Anchor Bolt

Tierod

Rockbolt

Soilnail

Post Tensions

Plates

Pretensions

Expansion Bolts

Fiber Rockbolt

Split Set

Regmiks

Nut Washer Eyebolt

BoltStud

Plastic Spacer

Tunnel Support Equipment