Anchorage

It is the connection of steel rebar into the concrete in the reinforced concrete construction. The covering is connected to the ground with anchorage bars (generally steel bars) on regular basis to keep the facade lining in the piles. The anchorage with one bar is made with drilling the ground, laying the steel bars into the hole and injecting the space around the bar (if available, by drawing casing pipe) by using 20-30 cm auger in diameter, drill or drifter, casing pipe if required.

- ► Easy and fast installation.

- ► No need for additional special tools.

- ► No torque requirement.

Anchorage

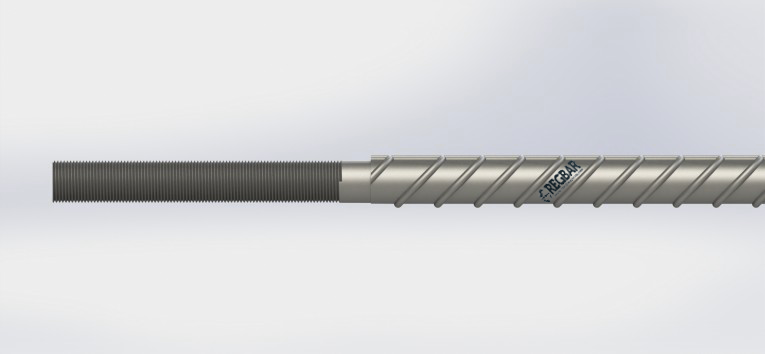

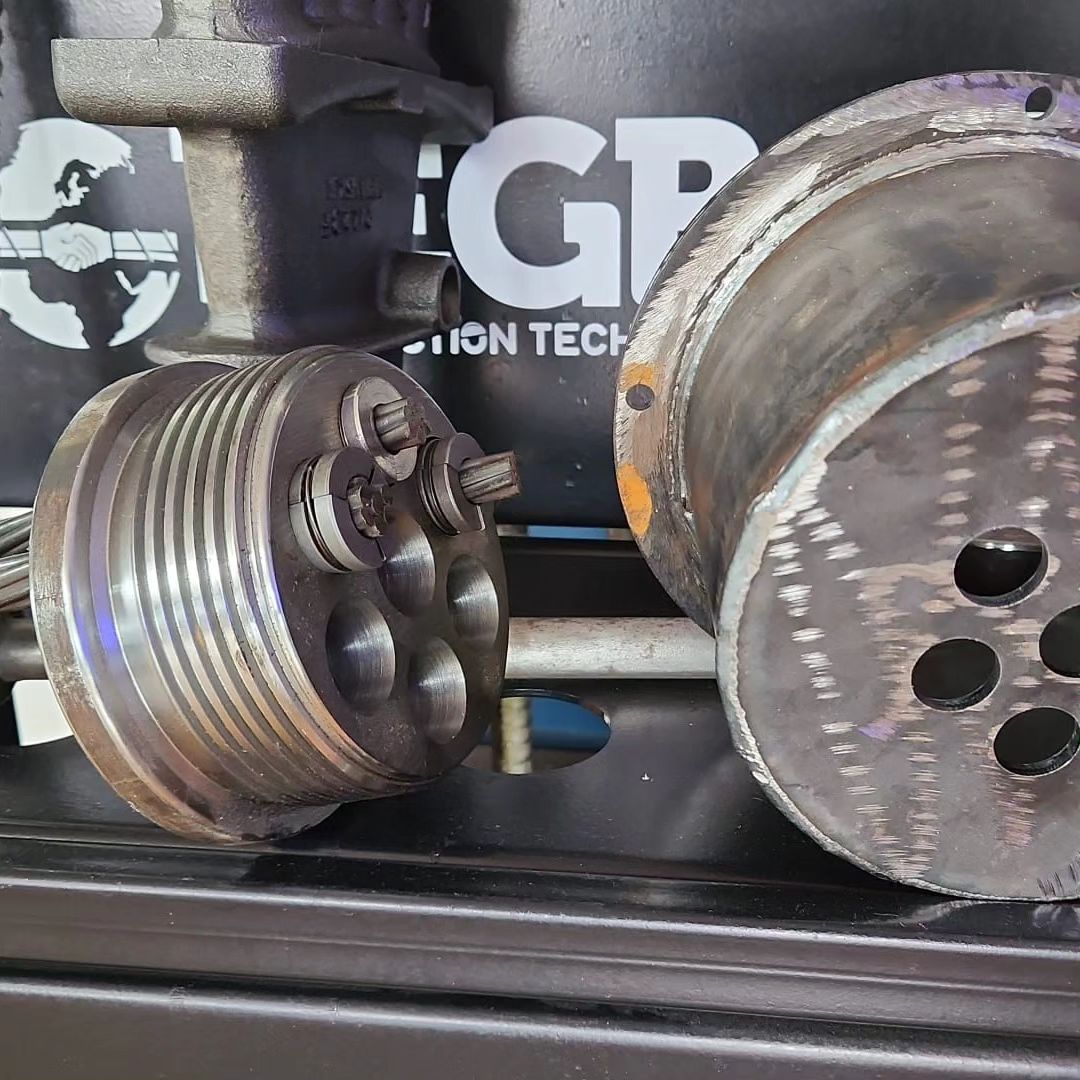

Regbar high-strength reinforcement threading machines enable flawless thread cutting in every quality of rebar detailed in below table. Mobile Regbar equipment enable on-site processing without the need to carry equipment. Thus, both the cost and time loss resulting from transportation of equipment is prevented and work is followed much better.

The injection is applied in the length out of active area. The anchorage bars are fixed to the facade lining. In some situations, the pre-stress is applied to the bars. While the anchorage bars drop by the tensile strength, it is met with frictions around the anchorage bars. To sum up, it is the process of mounting or fixing a block to a more durable and stable place behind it. It is the process of fixing the unstable soil to a more durable part behind it (sometimes to the durable soil behind it, sometimes to the available soil by trusting only the friction of the anchorage or to the reinforced concrete pile which is piled / poured on the back side before) in order to prevent the potential landslide. Regbar presents optimum solutions by carrying out the demanded anchorage threading in-place with the high technological mobile equipment sent to your site with no extra rebar logistic cost.

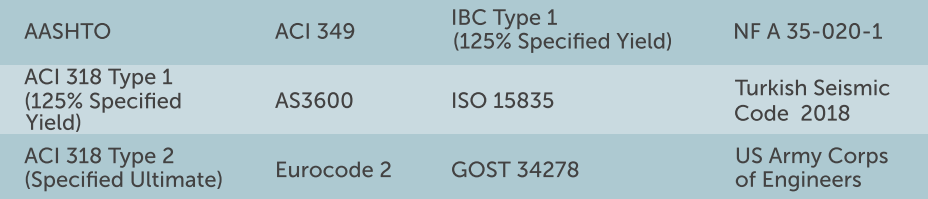

Anchorages are designed to meet or exceed major international building codes and Department of Transportation requirements, including:

More Information

Download the catalog to see all our productsContact us

Call us for Information and OfferWhy Us?

Global Company

Quality Control

Sale Support

Other Products

Tunnel Support

Equipments

Anchorage

Self Drilling Rockbolt

Anchor Bolt

Tierod

Rockbolt

Soilnail

Post Tensions

Plates

Pretensions

Expansion Bolts

Fiber Rockbolt

Split Set

Regmiks

Nut Washer Eyebolt

BoltStud

Plastic Spacer

Tunnel Support Equipment