TUNNEL SUPPORTS

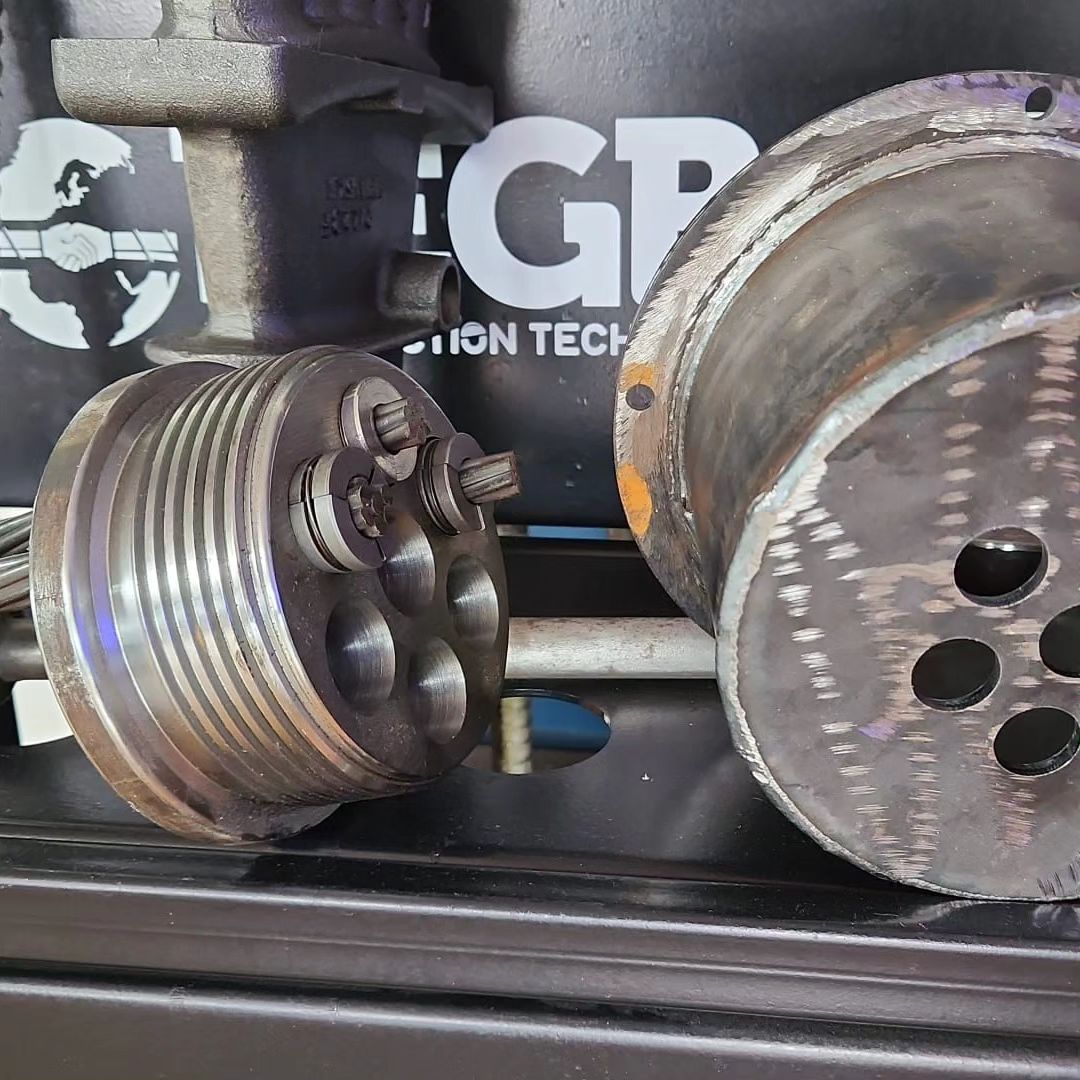

Segment Connection

Biblock system are circumferential connectors that can be custom desgined for tunnel segment production. 2 most commonly used sockets, 1 pin and 1 centering ring. In some types, the pin and centering ring are molded together. The cutting capacity is guaranteed by the centering ring followed by the pin. Tensile strength depends on pin / socket interaction. Different pins, sockets and centering rings are available

- Advantages;

- Cost savings per mold / ring;

- Fast segment setup;

- Safer field conditions;

- Less staff needed on the tunnel face;

- Better segment alignment;

- Smooth inner tunnel surface;

- Lower water friction in hydraulic tunnels;

- Dielectric insulation throughout the tunnel

- Lifting sockets can be used for a variety of precast Two functions

These designed sockets can be used with the TBM segment mounting system to lift the segments into place in the ring or for primary or secondary injection across the segments.

More Information

Download the catalog to see all our productsContact us

Call us for Information and OfferWhy Us?

Global Company

Quality Control

Sale Support

Other Products

Tunnel Support

Equipments

Tunnel Support

Anchorage

Tunnel Support

Self Drilling Rockbolt

Tunnel Support

Anchor Bolt

Tunnel Support

Tierod

Tunnel Support

Rockbolt

Tunnel Support

Soilnail

Tunnel Support

Post Tensions

Tunnel Support

Plates

Tunnel Support

Pretensions

Tunnel Support

Expansion Bolts

Tunnel Support

Fiber Rockbolt

Tunnel Support

Split Set

Tunnel Support

Regmiks

Tunnel Support

Nut Washer Eyebolt

Tunnel Support

BoltStud

Tunnel Support

Plastic Spacer

Tunnel Support

Tunnel Support Equipment

Tunnel Support