Introduction: Underground construction has become an integral part of modern infrastructure development, with tunnels playing a crucial role in transportation, utilities, and various other industries. One of the key elements that ensure the safety and stability of these tunnels is the specialized equipment designed for tunnel support. In this blog post, we will explore the importance of tunnel support equipment and its various applications in the world of underground construction.

The Basics of Tunnel Support Equipment: Tunnel support equipment encompasses a range of tools and machinery specifically engineered to address the challenges posed by underground environments. These include:

- Rock Bolts and Anchors:

- Rock bolts are used to reinforce the rock mass in tunnel walls, preventing potential collapses.

- Anchors provide additional support by distributing the load and stabilizing the surrounding rock.

- Shotcrete Machines:

- Shotcrete, a mixture of concrete and other additives, is sprayed onto tunnel surfaces to provide immediate support and prevent rockfall.

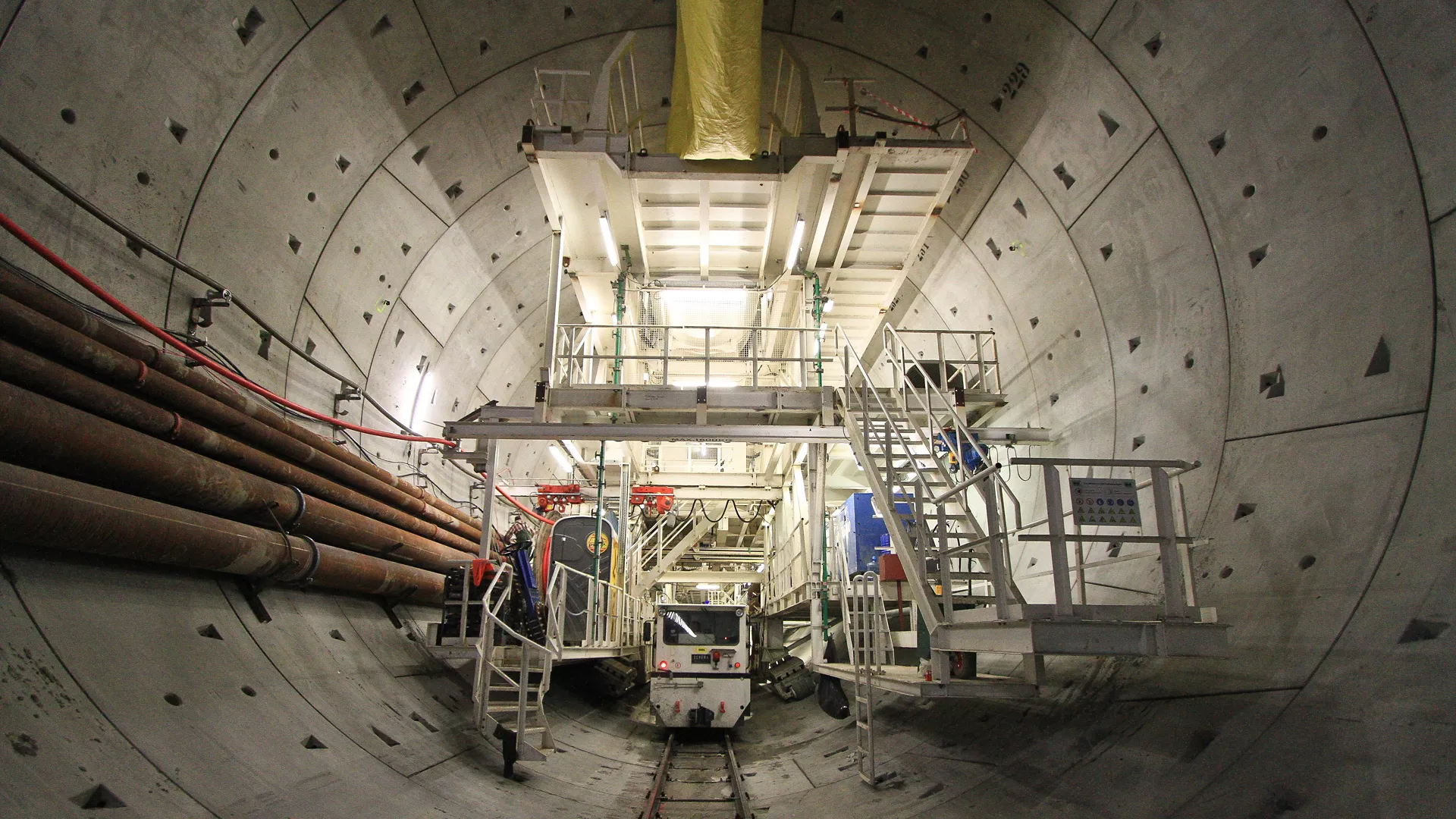

- Tunnel Boring Machines (TBMs):

- TBMs are massive machines that excavate tunnels by boring through the rock or soil, simultaneously installing the tunnel lining for structural support.

- Ground Freezing Equipment:

- In certain conditions, ground freezing may be necessary to stabilize the surrounding soil or rock mass during tunnel excavation.

Applications of Tunnel Support Equipment:

- Transportation Tunnels:

- Tunnel support equipment ensures the stability and safety of road, rail, and metro tunnels, allowing for efficient and secure transportation systems.

- Mining Tunnels:

- In mining operations, tunnel support equipment is used to create stable passages for extraction activities, preventing cave-ins and ensuring worker safety.

- Water and Sewer Tunnels:

- Tunneling equipment is employed in the construction of water supply and sewage tunnels, safeguarding these vital infrastructures.

Challenges and Innovations: The underground environment poses unique challenges, such as varying geological conditions and the need for quick, reliable support. Engineers and manufacturers are continually innovating tunnel support equipment to address these challenges, enhancing efficiency and safety in underground construction projects.

Conclusion: In conclusion, tunnel support equipment is the unsung hero of underground construction, providing the stability and safety necessary for the creation of tunnels that power our modern infrastructure. As technology continues to advance, we can expect further innovations in tunnel support equipment, shaping the future of underground construction.

Remember, this is just a sample blog post, and you can customize it based on your specific needs and preferences.